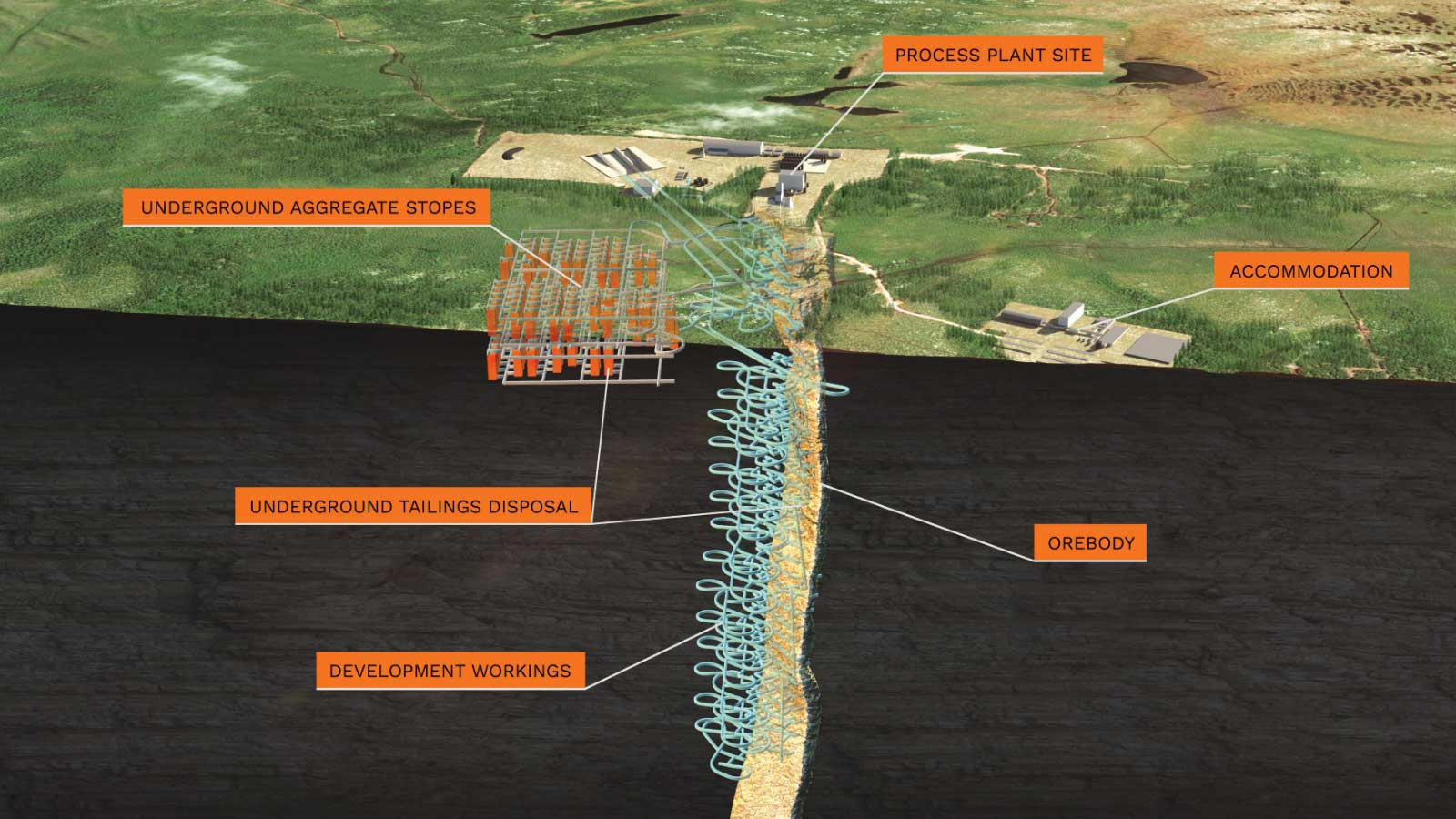

WHAT DO YOU DO AT RING OF FIRE METALS?

I am the Health, Safety & Environment (HSE) Coordinator at Esker Site. A role that I gladly accepted with Ring of Fire Metals while I was finishing my Bachelor of Arts in Indigenous Learning at Lakehead University this past April.

WHAT DOES A TYPICAL DAY LOOK LIKE FOR YOU?

I start my day at Esker Site by going for breakfast and greeting everybody with a good morning while enjoying a cup of coffee. During our morning toolbox meeting I am actively listening and engaging in the conversation, at times I will also give the toolbox safety talk.

After the meeting I usually head to the Esker Site office to input data into spreadsheets we use to organize our site operations. Other duties I would do throughout a rotation include conducting mock emergency scenarios, health and safety inspections, conducting orientations for new workers coming to Esker and organizing inventory.

WHAT DO YOU LIKE BEST ABOUT WORKING AT RING OF FIRE METALS?

I really enjoy the atmosphere and people that I work with. When you get a group of like-minded workers it makes the days go by quick and rotations enjoyable. The food is also great, and with the recent site renovations the Rec. Room is a great place to hang out after work hours and enjoy each others company.

HOW DO YOU SEE YOUR FUTURE AS RING OF FIRE METALS TRANSITIONS INTO AN OPERATING MINE?

I would like to one day be in a Supervisor/Managerial role with the company, everybody has to start somewhere, so I am glad I am able to get my start with Ring of Fire Metals as the HSE Coordinator. As time progresses, we all learn new skills and traits and we put that back into the work we do.

WHAT IS YOUR TOP SAFETY TIP?

Always wear personal protective equipment. Whether it’s footwear, high-visibility clothing, safety glasses, gloves, or safety equipment. Personal protective equipment can help minimize exposure to hazards and protect you from workplace injuries and illnesses.

Interested in working for Ring of Fire Metals?

Email careers@rofmetals.com or register an expression of interest on the careers page here.